Home > Aluminium profile

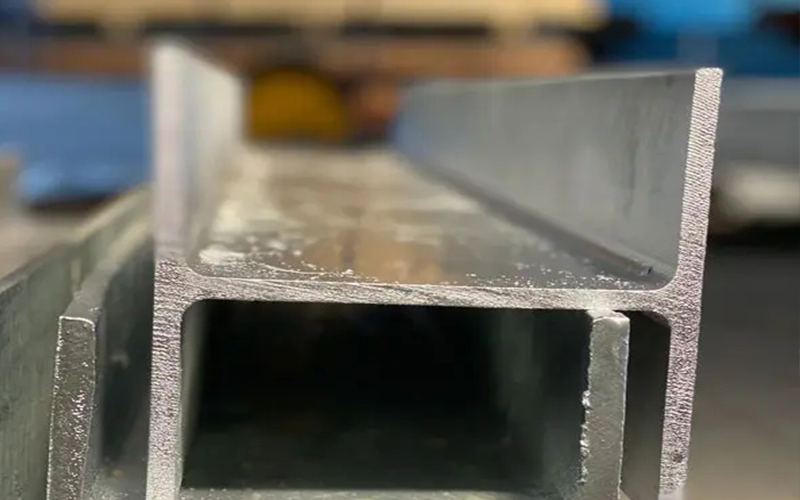

7075 Aluminum H-shaped steel

- Number:+8615065547531

- Whatsapp:+8615065547531

- Email:eve@sisnometals.com

- Product description:7075 Aluminum H-shaped steel

Product parameter

7075 Aluminum H-shaped steel is a high-strength, high-hardness and corrosion-resistant aluminum alloy H-shaped steel. It is known for its excellent mechanical properties and a wide range of applications. The following is a detailed introduction to 7075 aluminum H-shaped steel:

1. Composition and characteristics

Alloy composition: The main alloying elements of 7075 aluminum H-shaped steel include zinc and magnesium, of which the content of zinc is about 5-6% and the content of magnesium is about 2%. In addition, it may contain small amounts of other elements such as chromium and copper. The addition of these alloying elements significantly improves the strength, hardness and corrosion resistance of aluminum.

Mechanical properties: 7075 aluminum H-shaped steel has very high strength and hardness, and its tensile strength can reach more than 500 MPa, and the hardness is close to or exceeds some steel materials. This makes it perform well in situations where high loads and stresses are required.

Corrosion resistance: Due to the alloying action of zinc and magnesium, 7075 aluminum H-shaped steel has excellent corrosion resistance, especially in Marine and industrial environments. This makes it ideal for many harsh environments.

2. Characteristics of H-shaped steel

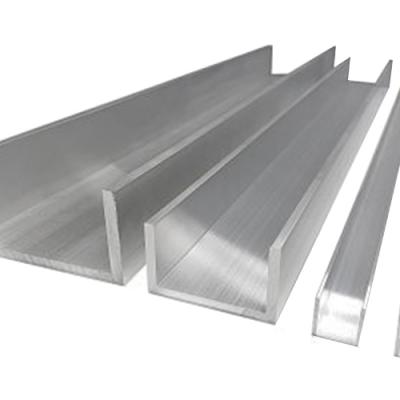

Section shape: The section shape of H-beam steel is "H" shape, wide flange, thin web, large section size, and large moment of inertia, which makes it have good bearing capacity and stability.

Light and high strength: Despite the high strength of 7075 aluminum H-shaped steel, its weight is relatively light due to the lightweight characteristics of aluminum. This makes it particularly popular in situations where high strength is required but light weight is required.

3. Application field

Aerospace: 7075 aluminum H-shaped steel has a wide range of applications in the aerospace field because of its high strength, high hardness and lightweight characteristics. It is often used in the manufacture of aircraft, rockets and other aircraft structural parts.

Automotive manufacturing: In automotive manufacturing, 7075 aluminum H-shaped steel is often used to manufacture key components such as body frames and suspension systems to improve the strength, durability and fuel economy of automobiles.

Shipbuilding: In shipbuilding, 7075 aluminum H-shaped steel is used to manufacture hull structures, masts and other components, and its corrosion resistance and high strength make it excellent in the Marine environment.

4. Processing and surface treatment

Processing properties: 7075 aluminum H-shaped steel has good processing properties, and can be processed by cutting, bending, welding, drilling and other processing technologies. However, due to its high strength and hardness, higher level tools and techniques may be required during processing.

Surface treatment: The surface can be decorated and protected by anodizing, spraying, electroplating, etc. These treatments can not only improve the corrosion resistance of 7075 aluminum H-shaped steel, but also give it a more beautiful appearance.

5. Precautions

Although 7075 aluminum H-shaped steel has excellent mechanical properties and corrosion resistance, it is still necessary to take appropriate protective measures in certain specific environments, such as strong acids, alkali or high temperature environments.

During processing and use, excessive heat treatment and mechanical damage should be avoided so as not to affect its performance and service life.

In summary, 7075 aluminum H-shaped steel is a kind of high-strength, high-hardness and corrosion-resistant aluminum alloy H-shaped steel, which is widely used in aerospace, automobile manufacturing, shipbuilding and other fields. Its light weight, high strength, good workability and corrosion resistance make it ideal for many demanding applications. Through proper processing and surface treatment, various requirements can be met.

Shape

H-channel

Technique

Hot Rolled

Thickness

5mm - 36.5mm

Application

Steel building

Length

6-12m

Flange Width

50-400mm

Flange

Thickness

8mm - 64mm

Web Width

100mm~900mm

Web Thickness

5mm - 36.5mm

Model Number

Customized

Processing

Service

Welding,

Punching, Cutting

Technique

Cold Rolled

Hot Rolled

Material

Aluminum

Material introduction

Aluminum has a rare variety of valuable properties. It is one of the lightest metals in the world: it is almost three times lighter than iron, but it is also extremely strong, extremely flexible, and resistant to corrosion because its surface is always covered with an extremely thin but very strong oxide film. It does not magnetize, is a good electrical conductor, and can form alloys with almost all other metals.

Aluminum can be easily processed by pressure in both hot and cold states. It can be rolled up, pulled and stamped. Aluminum doesn't catch fire, doesn't require special paint, and unlike plastic, it's not toxic. It is also very flexible, so it can be used to make sheets with a thickness of only 4 microns, as well as ultra-fine wire. The ultra-thin foil, made of aluminum, is three times thinner than a human hair. In addition, aluminum is more cost effective than other metals and materials.

Because aluminum easily forms compounds with other chemical elements, a wide variety of aluminum alloys have been developed. Even a very small amount of the mixture can dramatically change the properties of the metal, making it available for use in new areas. For example, in everyday life, you can find aluminum mixed with silicon and magnesium on the road, namely in the aluminum alloy wheels, engines, chassis and other components of modern cars. As for aluminum-zinc alloy, you probably have it in your hand right now, as this alloy is widely used in the production of mobile phones and tablets. At the same time, scientists continue to develop new aluminum alloys.

Modern construction, automotive, aviation, energy, food and other industries are inseparable from aluminum. In addition, aluminum has become a symbol of progress: all cutting-edge equipment and vehicles are made of aluminum.

It would seem that the combination of qualities listed above is enough to make aluminum the first choice in industry, however, there is another equally important property: aluminum can be reused again and again. Aluminum and its alloys can be melted and reused without compromising their mechanical properties. Scientists estimate that 1 kg of recycled aluminum cans can save up to 8 kg of bauxite, 4 kg of various fluorides and up to 15 KWH of electricity.

About 75% of the aluminum produced when the aluminum industry existed is still in use today.

Product testing

We know that in the steel industry, quality is the lifeline. As a professional steel manufacturer, we always put product quality in the first place and are committed to providing customers with the best quality and most reliable steel products.

In order to ensure that our products meet international standards and customer requirements, we have established a sound quality management system, from raw material procurement to production and processing, and then to finished product inspection, every link is strictly monitored and controlled. We use advanced production equipment and processes to ensure the accuracy and stability of products.

We know that only excellent quality products can win the trust of customers and market recognition. Therefore, we will continue to uphold the concept of quality first, constantly improve product quality and service level, to provide customers with better quality steel products and services.

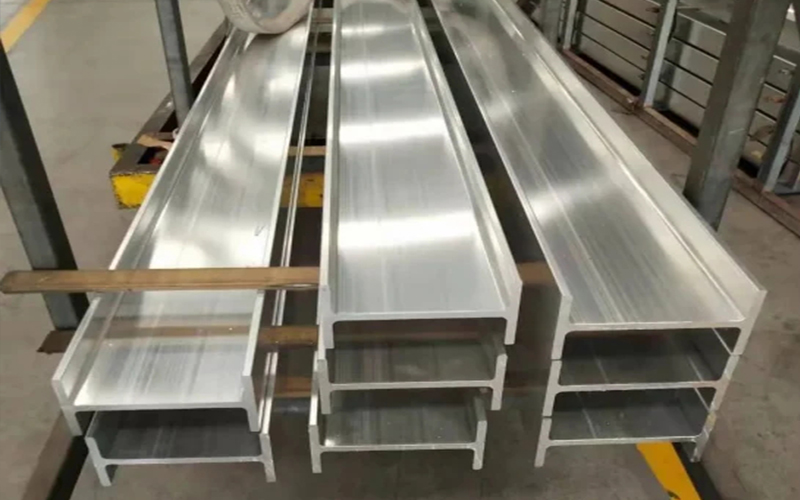

Warehouse and delivery show

Beijing Sisno Metals Trade Co.,Ltd has been committed to providing customers with a wide range of product choices. At present, we have a large stock of steel in our warehouses, covering a wide range of specifications and models to meet the diverse needs of different customers.

These stocks of steel are carefully selected by us for high quality products, which undergo strict quality control and inspection to ensure their excellent durability and reliability. We have a complete inventory management system, which can track and manage inventory in real time to ensure that the quality and quantity of products are always maintained in the best condition.

Our extensive inventory means we are able to respond quickly to our customers' needs, shorten lead times and provide a more flexible and convenient service. We are always customer-centric and committed to providing our customers with efficient and reliable solutions to help them achieve their engineering goals.

If you are interested in our stock status or have any questions, please feel free to contact us. We will be happy to provide you with more details and support to meet your needs.

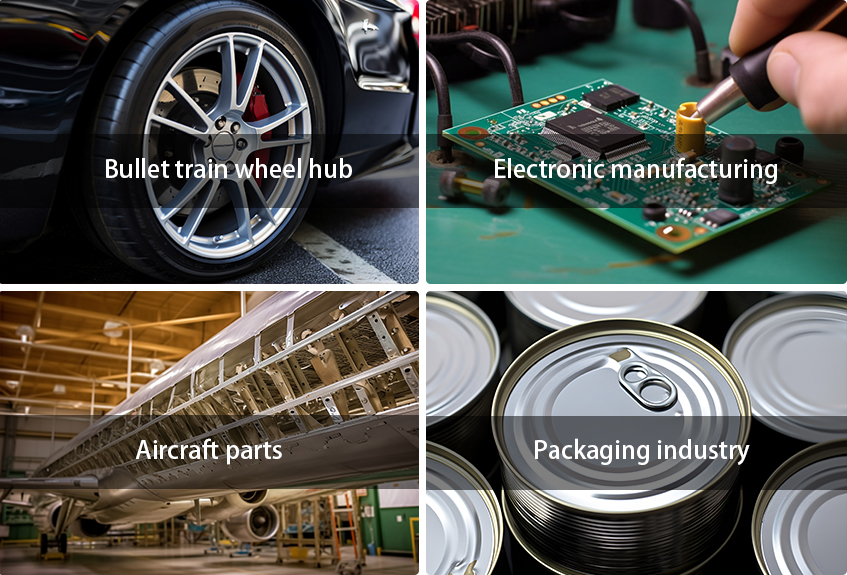

Product application

Aluminum, that is, aluminum alloy steel, is a metal material made of aluminum added to steel as an alloying element. Aluminum is used in a wide range of applications, and the following are some detailed application areas:

Aerospace: Aluminum has light weight, high strength and good corrosion resistance, so it is widely used in the aerospace field. For example, aircraft fuselages, engine components, and spacecraft structures may all use aluminum to reduce weight and improve performance.

Automobile manufacturing: Aluminum is also widely used in automobile manufacturing. It can be used to manufacture bodies, engine components, chassis and suspension systems, among others. The use of aluminum can reduce the weight of cars, improve fuel efficiency, and enhance the corrosion resistance of vehicles.

Buildings and structures: Aluminum also plays an important role in the construction sector. It can be used to make Bridges, tall buildings, stadiums and large facilities. Aluminum's high strength and lightweight properties make it ideal for these structures.

Shipbuilding: Aluminum is also used in shipbuilding. Due to its corrosion resistance and light weight, aluminum can be used in the manufacture of hulls, cabins and Marine equipment.

Electronics and electrical: Aluminum is also used in the electronics and electrical industry. It can be used to manufacture wires, cables, connectors and electronic components. Aluminum's electrical conductivity and corrosion resistance make it an ideal material for these applications.

In addition, aluminum can also be used in the manufacture of pressure vessels, plumbing systems, sports equipment, furniture and everyday items. With the continuous progress of science and technology and the continuous improvement of aluminum properties, its application areas will continue to expand.

About us

Welcome to Sesino Metal. Beijing Sesino Metal Trade Co., Ltd is an international trading company equipped with extensive experience and excellent reputation in the steel industry for more than 5 years. We are committed to providing customers with high-quality, diversified steel products to the global market. Since founding, we have always adhered to our core values of integrity, professionalism and innovation. Our team consists of a group of experienced industry experts and enthusiastic sales representatives, who have won the trust and praise of our customers with their deep industry knowledge and excellent service attitude.

As one of the world's leading steel products suppliers, we have established solid cooperative relationships with big state-owned steel mills in China, including Tisco, Wisco, Nisco, Shougang, Baosteel, Hunan Valin, and Shandongsteel ect, and many private mills who have more competitive prices. Therefore, we can provide you with a wide range of steel products, including carbon steel, stainless steel, alloy steel, oriented and non-oriented electrical silicon steel , aluminum steel and other metal products etc.

In addition to providing high-quality steel products, we are also committed to providing comprehensive solutions to our customers. Our professional team will provide you with customized procurement solutions, logistics arrangements and after-sales services based on your needs to ensure that you receive worry-free support and protection during the entire transaction process.

We understand that our customers' needs and satisfaction are the keys to our success. Therefore, we will continue to work hard to improve service quality, continuously develop and improve product lines to meet the changing needs of customers. We look forward to establishing a long-term and stable cooperative relationship with you and creating a better future together. Thank you for choosing Sesino Metals, we look forward to working with you to create our brilliance!

Certificate display

We value product quality and customer service feedback, so all our products can accept professional quality inspection by third party testing agencies and can be accompanied by relevant quality certificates

FAQ

Are you having any problems? You can always ask us about your problems, or you can browse the topics below to find what you are looking for.

Are you trading company or manufacturer ?

We are specialized in the production and processing of various carbon steel products, we can also accept custom products of other materials

How long is your delivery time?

It takes around 3-5 days for the regular models, and 7 to 10 working days for the special sizes and processing. It is based on the order quantity and requirement.

Do you provide samples ? Is it free or extra ?

We can provide samples to you for free, but the cost of express delivery will be borne by you.

Do you support customization ?

Yes, we have a full stock of products with a full range of models and a working production line. If you don't have what you want, we can customize it.

Do you accept third party testing ?

Yes, we fully accept the quality inspection of the third party inspection institutions. We attach great importance to the reliability of product quality

What are the advantages of your company?

First of all, we have an absolute advantage in price. Secondly, the quality of products is also strictly controlled.

Latest News

- Talk about your understanding 2024-04-19

- PPGI Production Process2024-04-19

- Property characteristics and h2024-04-19

- Application of round steel in 2024-04-19

- Shipbuilding steel2024-04-19

Product Ctegory

Contact

CONTACT USContact:+86 18710031487

Phone: +86-15065547531

Email:eve@sisnometals.com

Whatsapp: +86-15065547531