Home > Cold-rolled oriented silicon steel

Cold rolled grain oriented silicon steel

- Number:+8615065547531

- Whatsapp:+8615065547531

- Email:eve@sisnometals.com

- Product description:Cold rolled grain oriented silicon steel

Product parameter

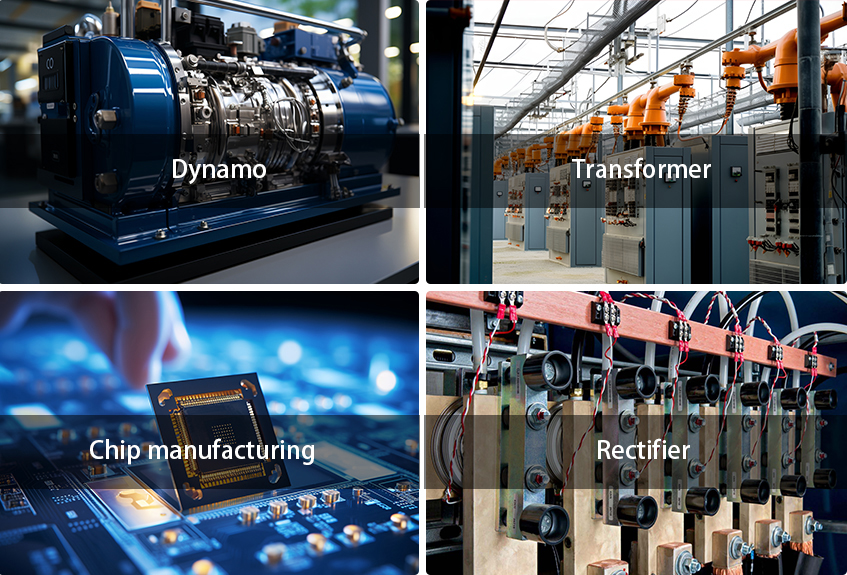

Cold-rolled oriented silicon steel is a kind of high quality electrical material, widely used in power equipment, motors, transformers and other fields.

Cold-rolled oriented silicon steel, also known as cold-rolled transformer steel, is an important ferrosilicon alloy used in transformer (iron core) manufacturing industry. Its production process is complex, manufacturing technology is strict, mainly divided into ordinary oriented silicon steel (CGO) and high magnetic induction oriented silicon steel (HiB). Cold-rolled oriented silicon steel process is to cold-rolled silicon steel sheet to make its orientation better, so as to improve its magnetic permeability and magnetoimpedance ratio of electromagnetic properties. The choice of raw materials is very important, the raw material of cold-rolled oriented silicon steel is mainly silicon steel sheet, silicon steel sheet is a kind of electrical material with high permeability, low magnetic loss and low iron loss, its manufacturing needs to choose high quality, low magnetic susceptibility silicon steel plate as a raw material.

Standard

AiSi, ASTM,

DIN, GB, JIS, AISI, ASTM

Technique

Cold Rolled

Thickness

0.1 - 0.3 mm

Surface

Treatment

black

galvanized coated oiled painting

Shape

plate,coil

Processing

Service

Bending,

Welding, Decoiling, Cutting, Punching

Product Name

Cold Rolled

Oriented Silicon Steel

Surface

black

galvanized coat oiled painting,etc

Advantage

Corrosion

oxidation resistance, thermal stability machinable

Application

compressor

motor,electric machinery,rectifier,transformer,etc.

Invoicing

by theoretical

weight

Key words

silicon steel

sheets

Silicon

content

0.5 ~ 4.5%

Material introduction

Silicon steel is a special kind of steel, its main feature is that it contains a high proportion of silicon elements, usually silicon content between 0.8% and 4.8%. The characteristics and applications of silicon steel make it widely used in many fields such as electrical, electronic, communication, automotive and so on.

The characteristics of silicon steel:

High permeability: Silicon steel has high permeability, which means that it can effectively conduct magnetic fields and is an ideal material for manufacturing electrical equipment such as transformers and motors.

Low iron loss: The iron loss of silicon steel is low, that is, the energy loss generated when the magnetic field changes is small, which helps to improve the efficiency of electrical equipment and extend the service life.

Good processing performance: silicon steel has good plasticity, toughness and weldability, easy to process into a variety of shapes and sizes, convenient to manufacture a variety of electrical equipment.

High resistivity: Silicon steel has a high resistivity, which helps to reduce eddy current losses in electrical equipment and improve the efficiency of equipment.

Good corrosion resistance: silicon steel has good corrosion resistance and can be used for a long time in harsh environments.

Silicon steel production process:

The production process of silicon steel is relatively complex, mainly including steelmaking, continuous casting, hot rolling, pickling, cold rolling, annealing and other processes. In the production process, it is necessary to strictly control the ratio of charge, melting temperature, rolling speed and other parameters to obtain high quality silicon steel products.

The following is a detailed introduction to the difference and role of cold-rolled oriented silicon steel and cold-rolled non-oriented silicon steel:

The difference:

Properties: Oriented silicon steel is an important ferrosilicon alloy used in transformer (iron core) manufacturing industry, and unoriented silicon steel is a very low carbon ferrosilicon alloy, its grains are irregularly oriented distribution.

Characteristics: The magnetic properties of oriented silicon steel are strongly directional, with the lowest iron loss and highest permeability in the rolling direction, and high magnetic inductance in a certain magnetization field. Non-oriented silicon steel has good electromagnetic properties and processing properties.

Purpose: Oriented silicon steel is mainly used in transformer manufacturing, while non-oriented silicon steel is widely used in electrical equipment such as motors, generators, transformers.

Functions:

Cold-rolled oriented silicon steel: Because of its superior high permeability and low loss characteristics, it is widely used in the manufacturing of electrical equipment such as transformers and motors, especially in the occasions requiring high efficiency and low energy consumption, such as power, electronics, communications and other fields.

Cold-rolled non-oriented silicon steel: mainly used in generator manufacturing, because it has good electromagnetic properties and processing properties, can meet the requirements of the generator for materials, such as high strength, high conductivity, high corrosion resistance and so on.

In short, although cold-rolled oriented silicon steel and cold-rolled unoriented silicon steel are both silicon steel materials, their properties, characteristics, uses and functions are very different. In practical applications, the appropriate materials need to be selected according to the specific use occasions and requirements.

Product testing

We know that in the steel industry, quality is the lifeline. As a professional steel manufacturer, we always put product quality in the first place and are committed to providing customers with the best quality and most reliable steel products.

In order to ensure that our products meet international standards and customer requirements, we have established a sound quality management system, from raw material procurement to production and processing, and then to finished product inspection, every link is strictly monitored and controlled. We use advanced production equipment and processes to ensure the accuracy and stability of products.

We know that only excellent quality products can win the trust of customers and market recognition. Therefore, we will continue to uphold the concept of quality first, constantly improve product quality and service level, to provide customers with better quality steel products and services.

Warehouse and delivery show

Beijing Sisno Metals Trade Co.,Ltd has been committed to providing customers with a wide range of product choices. At present, we have a large stock of steel in our warehouses, covering a wide range of specifications and models to meet the diverse needs of different customers.

These stocks of steel are carefully selected by us for high quality products, which undergo strict quality control and inspection to ensure their excellent durability and reliability. We have a complete inventory management system, which can track and manage inventory in real time to ensure that the quality and quantity of products are always maintained in the best condition.

Our extensive inventory means we are able to respond quickly to our customers' needs, shorten lead times and provide a more flexible and convenient service. We are always customer-centric and committed to providing our customers with efficient and reliable solutions to help them achieve their engineering goals.

If you are interested in our stock status or have any questions, please feel free to contact us. We will be happy to provide you with more details and support to meet your needs.

Product application

Cold-rolled oriented silicon steel is a kind of high quality electrical material, widely used in power equipment, motors, transformers and other fields.

Cold-rolled oriented silicon steel, also known as cold-rolled transformer steel, is an important ferrosilicon alloy used in transformer (iron core) manufacturing industry. Its production process is complex, manufacturing technology is strict, mainly divided into ordinary oriented silicon steel (CGO) and high magnetic induction oriented silicon steel (HiB). Cold-rolled oriented silicon steel process is to cold-rolled silicon steel sheet to make its orientation better, so as to improve its magnetic permeability and magnetoimpedance ratio of electromagnetic properties. The choice of raw materials is very important, the raw material of cold-rolled oriented silicon steel is mainly silicon steel sheet, silicon steel sheet is a kind of electrical material with high permeability, low magnetic loss and low iron loss, its manufacturing needs to choose high quality, low magnetic susceptibility silicon steel plate as a raw material.

The oriented silicon steel consumes less power per unit mass, which can reduce the power loss of transmission and distribution lines and achieve energy saving effect. It has strong magnetic directivity, superior high permeability and low loss in the rolling direction of easy magnetization, and is a key functional soft magnetic material to improve the performance of transformers.

About us

Welcome to Sesino Metal. Beijing Sesino Metal Trade Co., Ltd is an international trading company equipped with extensive experience and excellent reputation in the steel industry for more than 5 years. We are committed to providing customers with high-quality, diversified steel products to the global market. Since founding, we have always adhered to our core values of integrity, professionalism and innovation. Our team consists of a group of experienced industry experts and enthusiastic sales representatives, who have won the trust and praise of our customers with their deep industry knowledge and excellent service attitude.

As one of the world's leading steel products suppliers, we have established solid cooperative relationships with big state-owned steel mills in China, including Tisco, Wisco, Nisco, Shougang, Baosteel, Hunan Valin, and Shandongsteel ect, and many private mills who have more competitive prices. Therefore, we can provide you with a wide range of steel products, including carbon steel, stainless steel, alloy steel, oriented and non-oriented electrical silicon steel , aluminum steel and other metal products etc.

In addition to providing high-quality steel products, we are also committed to providing comprehensive solutions to our customers. Our professional team will provide you with customized procurement solutions, logistics arrangements and after-sales services based on your needs to ensure that you receive worry-free support and protection during the entire transaction process.

We understand that our customers' needs and satisfaction are the keys to our success. Therefore, we will continue to work hard to improve service quality, continuously develop and improve product lines to meet the changing needs of customers. We look forward to establishing a long-term and stable cooperative relationship with you and creating a better future together. Thank you for choosing Sesino Metals, we look forward to working with you to create our brilliance!

Certificate display

We value product quality and customer service feedback, so all our products can accept professional quality inspection by third party testing agencies and can be accompanied by relevant quality certificates

FAQ

Are you having any problems? You can always ask us about your problems, or you can browse the topics below to find what you are looking for.

Are you trading company or manufacturer ?

We are specialized in the production and processing of various carbon steel products, we can also accept custom products of other materials

How long is your delivery time?

It takes around 3-5 days for the regular models, and 7 to 10 working days for the special sizes and processing. It is based on the order quantity and requirement.

Do you provide samples ? Is it free or extra ?

We can provide samples to you for free, but the cost of express delivery will be borne by you.

Do you support customization ?

Yes, we have a full stock of products with a full range of models and a working production line. If you don't have what you want, we can customize it.

Do you accept third party testing ?

Yes, we fully accept the quality inspection of the third party inspection institutions. We attach great importance to the reliability of product quality

What are the advantages of your company?

First of all, we have an absolute advantage in price. Secondly, the quality of products is also strictly controlled.

Latest News

- Talk about your understanding 2024-04-19

- PPGI Production Process2024-04-19

- Property characteristics and h2024-04-19

- Application of round steel in 2024-04-19

- Shipbuilding steel2024-04-19

Product Ctegory

Contact

CONTACT USContact:+86 18710031487

Phone: +86-15065547531

Email:eve@sisnometals.com

Whatsapp: +86-15065547531